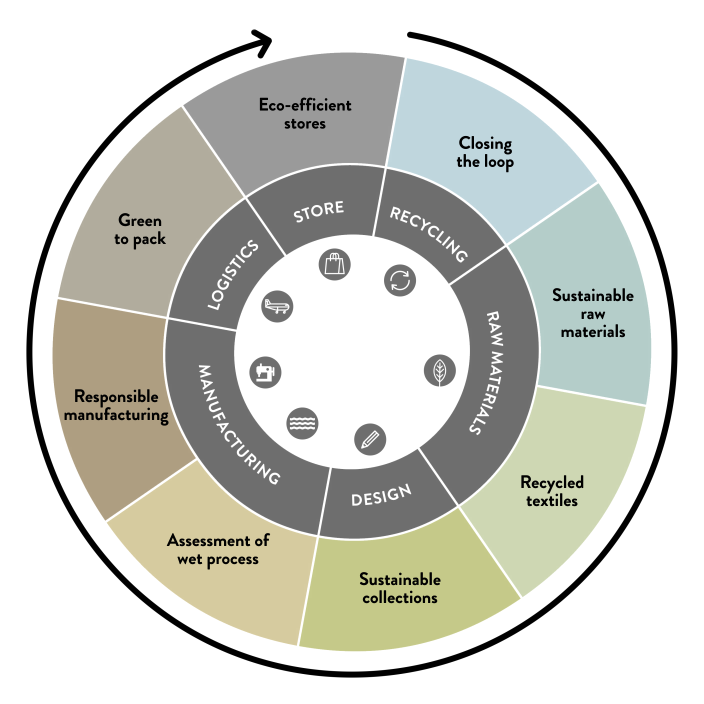

Towards a circular economy

RIGHT TO WEAR: RESPONSIBILITY IN ALL PRODUCTION STAGES

In order to bring the latest fashion trends to our stores as demanded by our customers, a lengthy process is required from selecting the materials to the printing or distribution of items. Following our Right to Wear sustainability philosophy, over 1,500 professionals, both at Inditex and our scientific and technological partners, ensure that we are responsible in each phase of our production cycle. In this rigorous task, we demand internal standard guidelines for all stages of the life of the product in order to create items that are ethical, healthy and environmentally friendly.

Sustainable raw materials

Environmentally responsible textiles

In the development of our garments, we focus on incorporating textiles that allow us to reduce our environmental impact and to protect biodiversity, such as organic cotton, which does not require fertilisers or chemical pesticides, or TENCEL® Lyocell, a fiber originated from wood from forests that are managed in a sustainable way.

Recycled textiles

New recycled fibres

Inditex incorporates recycled polyester, wool and cotton in its garments, fibres where manufacturing consumes less water, energy and natural resources than the production of new fibres. Moreover, the Group has initiated new lines of research to improve the recycling of textile fibres together with the Massachusetts Institute of Technology (MIT). And through the collaboration with Austrian company Lenzing, we have developed Refibra™Lyocell, from cotton waste generated by Inditex and wood originated from forests that are managed sustainably.

Sustainable collections

Join Life and Wear the Change

To enable our customers to quickly identify the products that stand out as environmentally friendly, some Inditex brands have launched specific collections of more sustainable products. Zara identifies these products with the Join Life label, whereas in Oysho, the use of raw materials such as organic cotton, TENCEL®Lyocell or recycled materials is recognised from the Wear the Change label.

Responsible manufacturing and Evaluation of wet processes

Clear to Wear & Safe to Wear

These are health and safety standards for products by the Inditex Group, of obligatory application for all of our garments and incorporating the most strict and up-to-date legislation in this area.

Picking Programme

This is an inspection and analysis instrument designed by Inditex and adapted to its production and logistic model. Its objective is to ensure that all items that we sell comply with our product health and safety standards.

The List by Inditex

A pioneering global programme to improve the quality of the chemical products used in the manufacturing of textile and leather products. Through manufacturing and product analyses audits and later classification, improvements in the use of these chemical substances are implemented with two objectives: Zero Discharge of Hazardous Chemicals (environmental) and Clear to Wear (product).

Ready to Manufacture

Ready to Manufacture is a code of good manufacturing practices for textile and leather products for facilities that undertake wet processes (dyeing, washing, tanneries and printing) and that guarantees compliance with the demanding health standards of Inditex.

Green to Wear

This is a standard that guarantees that our production processes are environmentally responsible, including criteria for evaluation and control of the supply chain. We work with this principle in order to ensure efficient consumption of the resources used, from raw material sourcing to sale.

Green to Pack

This programme aims to reduce the consumption of raw materials in our packaging and to improve shipment density, increasing the amount of products transported in each shipment. Additionally, the use of more sustainable materials in our packaging was encouraged, improving re-use and subsequent separation and recycling.

Eco-efficient store

Inditex stores incorporate the most innovative technology to facilitate energy saving and management, thus reducing the emissions of carbon dioxide (CO2). The sustainability and energy efficiency measures implemented in these stores contribute savings of 20% in the case of electricity, and 40% in water consumption compared to conventional stores.

Closing the Loop

Use and end of life of the product

In order to lengthen the useful life of garments, we have a project for the reuse or recycling of garments in partnership with the third sector, recycling companies and textile manufacturers.