1. Identification of the supply chain

The first step towards ensuring sustainability in the supply chain is to identify its components. To this end, Inditex maintains close relations with its suppliers in order to create programmes tailored to their situation and in line with the Group’s business model. In order to correctly identify and get to know suppliers, efforts are made to ensure traceability, provide training to auditors and implement continual improvements in auditing quality. In 2014, Inditex’s supply chain was made up of 1,625 suppliers.

Traceability

Production traceability is the first step towards developing all the policies and activities involved in the sustainable management of the supply chain. In 2014, the establishment of production audits in supplier clusters was Inditex’s primary objective in the sphere of traceability. An emphasis on traceability promotes the correct management of supply activities by purchasing teams, and increases product safety.

Based on an analysis of the information entered by suppliers into Inditex’s online Manufacturer Management System, production audits allow an assessment of capacities, processes and time frames, and ensure that all production units are correctly declared and approved. This method guarantees that all workers involved in Inditex’s production are covered by the programmes set out in the Code of Conduct, designed to protect their rights.

Thanks to the consolidation of the online Manufacturer Management System designed by Inditex in 2013 to meet the Group’s needs in traceability, during 2014 more than 2,400 production audits were performed; that is, triple the number carried out in the previous year. All of the suppliers in the supply chain manage their portfolio of manufacturers and exchange updated information on manufacturers with Inditex.

Production audits performed in 2014

| Geographic area | Production audits | |

|---|---|---|

| 2014 | 2013 | |

| Africa | 163 | 307 |

| America | 1,751 | 347 |

| Asia | 488 | 82 |

| Europe (non-EU) | 57 | 84 |

| European Union | 4 | n/a |

| Total | 2,463 | 820 |

As a result of the 2,463 production audits performed in 2014, 266 breaches were detected, giving a compliance rate of 89%. Most of the breaches entailed that the supplier did not properly report to Inditex all the factories that took part in its production. Each and every case is analysed by Inditex’s CSR teams, who apply the maxim used throughout the Strategic Plan: opportunities are given for improvement, but there is zero tolerance in the case of repeated non-compliance.

(*) Suppliers of fashion items, mainly clothing, footwear and accessories, with a production of over 20,000 units. Suppliers with smaller production account for 0.43% of total production.

(**) Textile, footwear and accessories factories declared as active by suppliers of fashion items – mainly clothing, footwear and accessories – with a production of over 20,000 units.

The Inditex supply chain in 2014

| Geographic area | Suppliers with purchase 2013 | PSuppliers not used 2014 | New suppliers for 2014 | Suppliers with purchase 2014 |

|---|---|---|---|---|

| Africa | 124 | 21 | 32 | 135 |

| America | 82 | 26 | 24 | 80 |

| Asia | 738 | 185 | 206 | 759 |

| Europe (non-EU) | 151 | 38 | 47 | 160 |

| European Union | 497 | 99 | 93 | 491 |

| Total | 1,592 | 369 | 402 | 1,625 |

Breaches detected in 2014:

| Geographic area | Breaches detected: |

|---|---|

| Africa | 40 |

| America | 12 |

| Asia | 174 |

| Europe (non-EU) | 40 |

| European Union | 0 |

| Total | 266 |

As of 2015, the aim is to perfect this methodology, incorporating the best practices for analysing manufacturer capacities, making it possible to obtain better technical information on all processes and product types, thereby gaining a realistic vision of the productive capacities of each factory.

Integration of traceability systems

During 2014, work continued to integrate all data related to production traceability into a single system designed to suit the needs of Inditex’s business model. Environment, product health and safety, and compliance areas can access information on orders and product manufacturing from a single database. In turn, they add to this information the results and assessments from their control and auditing programmes, allowing purchasing teams and suppliers to gain access in real time to information on the behaviour of the supply chain in relation to Inditex’s standards.

Training for auditors

In 2014, some 46 internal auditors and 827 external auditors have worked to ensure that all suppliers comply with the Code of Conduct and to establish corrective plans to deal with any breaches of the Code of Conduct.

Auditors have an important role in verifying compliance with the Code in all factories: this means that their training and capacity building is key. Inditex’s CSR teams regularly train new auditors and provide specific training on certain provisions of the Code of Conduct.

In 2014, some 361 external and internal auditors received training in all supplier clusters. This included various internal auditors working for Inditex who gained qualifications related to Social Accountability International’s SA8000 standard.

Auditors trained in 2014

| Geographic area | Training | Auditors trained |

|---|---|---|

| Africa | 1 | 7 |

| America | 7 | 33 |

| Asia | 19 | 184 |

| Europe (non-EU) | 22 | 85 |

| European Union | 13 | 52 |

| Total | 62 | 361 |

Training courses are designed to strengthen concepts or further explore aspects that lead to better quality audits and ensure that Inditex’s methods and requirements are applied systematically in all assessments.

Training for young experts

Inditex has an agreement with the Catholic University of Portugal, Porto on the training of students in the performance of social audits. Students gain work experience as auditors in Inditex, putting into practice the knowledge and skills acquired during their studies. Fourteen young people were selected and trained in 2014, performing social audits for Inditex and developing their analytical and management skills in an opportunity that for many was their first experience of the professional world.

Audit quality management

Inditex is conscious of the fact that suppliers are subject to a great number of social audits involving various companies and standards (audit fatigue syndrome), and seeks to provide supply chain control solutions that go beyond the sphere of auditing. One essential step in this process is ensuring the quality of audits, guaranteeing that they are carried out correctly and that results are used for actions as part of sustainability and improvement programmes. Moreover, the scope of auditing extends to all tiers of production, providing exhaustive knowledge on the supply chain.

In 2014, Inditex’s methods of performing social audits were updated in order to simplify the process and improve the quality of information obtained. The methodology employed until now, designed in 2007 in conjunction with the International Textile, Garment and Leather Workers' Federation (ITGLWF) – which has now been integrated into the new international industry trade union federation IndustriALL Global Union – and the Cambridge Centre for Business and Public Sector Ethics, is regularly revised in order to bring in all the changes and experiences accumulated over time.

The new methodology gives auditors more independence, allowing them to provide a realistic and complete overview of each factory, covering concepts such as decent wages, worker health and safety, and management systems, in greater depth.

Main advances in the new methodology for social audits

| Old methodology | New methodology | |

|---|---|---|

| Documentation | Five questionnaires to be completed by the auditor | Single, simpler but more wide-ranging questionnaire |

| Auditor maturity and professionalism | The auditor collects information and captures it in the audit | The auditor collects information, analyses the information and provides conclusions |

| Management systems | Separate assessment of each aspect of management | Comprehensive assessment providing a better overall vision of management systems |

| Worker health and safety | Verification of compliance with health and safety via interviews, visual inspection and information gathering | In-depth investigation of aspects concerning building stability and worker safety |

| Traceability | Gathering information on traceability through interviews and visual inspections | Strengthening procedures and documentation related to traceability issues |

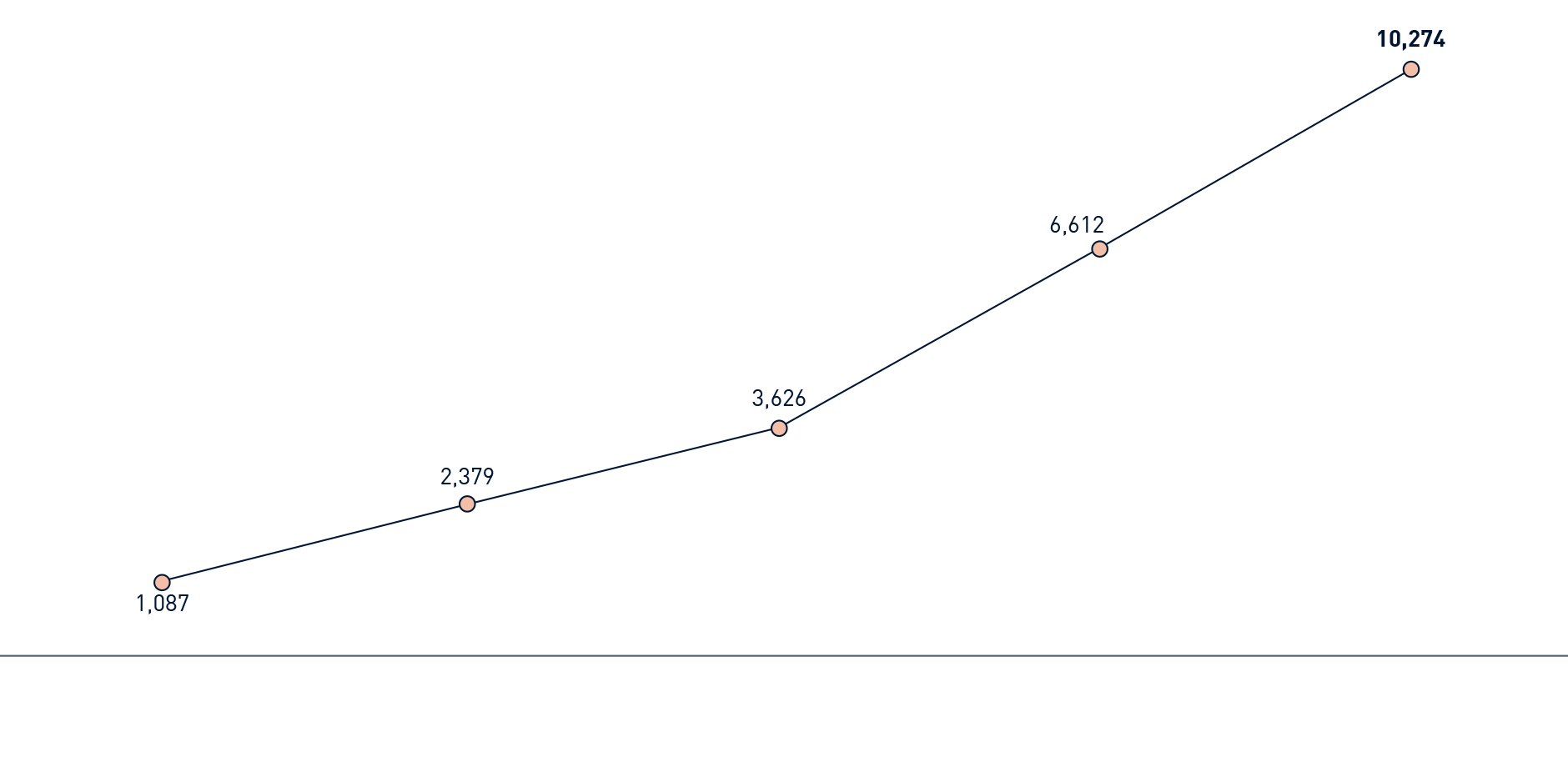

Audits performed on manufacturers in 2014 by geographic area and type

| Sociales | ||||||

|---|---|---|---|---|---|---|

| Geographic area | Pre-Assessment | Initial | Follow-up | Special (*) | Production | Total |

| Africa | 74 | 100 | 45 | 462 | 163 | 844 |

| America | 154 | 251 | 153 | 2 | 1,751 | 2,311 |

| Asia | 1,199 | 1,143 | 580 | 1,030 | 488 | 4,440 |

| Europe (non-EU) | 441 | 513 | 223 | 24 | 57 | 1,258 |

| European Union | 499 | 789 | 96 | 33 | 4 | 1,421 |

| Total | 2,367 | 2,796 | 1,097 | 1,551 | 2,463 | 10,274 |

(*) Special audits include health and safety checks, and visits to verify the level of compliance with Corrective Action Plans, among others

Pre-assessment audits

Pre-assessment consists of a preliminary evaluation of potential suppliers and factories performed by internal and external auditors without prior notice. Only those meeting the requirements established by Inditex in its Code of Conduct can enter the supply chain. From that moment forth, they are subject to the Code of Conduct and to the standards set out in the Inditex Minimum Requirements.

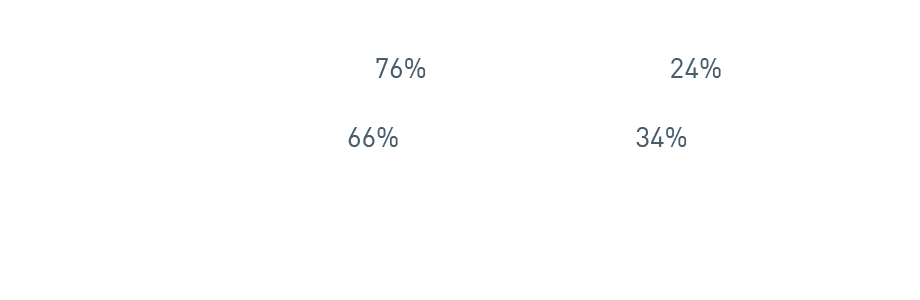

| Geographic area | Pre-assessment audits | % deemed suitable |

|---|---|---|

| Africa | 74 | 77% |

| America | 154 | 64% |

| Asia | 1,199 | 69% |

| Europe (non-EU) | 441 | 85% |

| European Union | 499 | 89% |

| Total | 2,367 | 76% |

In 2014, of the 2,367 pre-assessment audits performed on potential suppliers, 76% were considered to be suitable to produce goods for Inditex, 10% more than in 2013. This increase, compared with the previous year, demonstrates the trend for increasing awareness among textile suppliers and manufacturers of the minimum sustainability standards that they must respect, as well as the internal awareness among Inditex’s purchasing teams when selecting suppliers.

Social audits

Each and every one of the suppliers and manufacturers in the Inditex supply chain is subject to regular social audits. There is always an initial audit when a supplier begins working with Inditex, as well as follow-up audits. The aim is to verify their compliance with the Code of Conduct and to establish Corrective Action Plans (CAPs) intended to ensure that fundamental labour rights are respected.

A supplier or factory that has gained the maximum classification (A grade) is always subject to an audit at least every two years. Audit frequency increases progressively according to the level of breaches of compliance detected.

The audits are performed on all levels of production and are carried out both by internal auditors and certified external auditors, without prior notification of the date the visit is to be performed. In 2014, some 3,893 social audits were performed on potential suppliers and factories.

Special audits

The more than 1,500 special audits performed in 2014 consisted of visits and inspections related to specific issues such as worker health and safety, and competence visits to ensure compliance with the Corrective Action Plans. These audits include, for instance, the inspection of laundry processes to ensure that the sandblasting process, which is prohibited by Inditex, is not in use.

Implementation of a new methodology for social audits

The new methodology for social audits was launched throughout the Group at the end of 2014, having been agreed with the IndustriALL Global Union and shared with internal and external auditing teams, who contributed their comments and suggestions. Prior to the launch, auditors had received theoretical and practical training as part of a “train the trainer” process. These auditors are now working with the new methodology in all audit processes.

Production audits

Production audits are intended to guarantee the traceability of the supply chain from the analysis of the information gathered in the Manufacturer Management System.