Manufacturing responsible products

Objective

Manufacturing responsible products

Opportunity

Constant improvement of quality, health and safety of products

Material issues

5. Product quality, health and safety

11. Changes in regulation

23. Animal welfare

30. Dialogue with and commitment to stakeholders

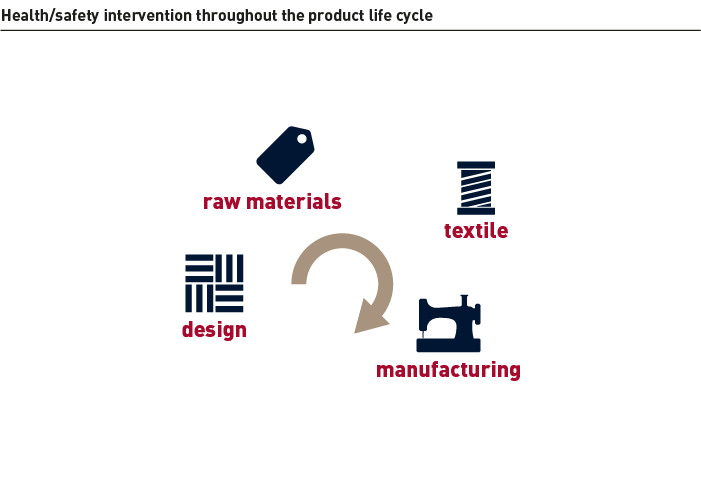

Inditex’s commitment to its customers includes guaranteeing that all products marketed by the group meet the most demanding health and safety standards in the world. Inditex’s strategy in this field covers all phases of production, from design to manufacture and distribution.

The objective is to study, regulate and supervise all the methods, processes and installations involved in production. All of these elements are analysed separately and together in order to continuously improve the quality of the products, increase efficiency in the use of resources and reduce any potential impact on the environment. This strategy is also specifically designed for Inditex, which allows it to be adjusted to the characteristics of the supply chain.

To work towards this commitment, Inditex, in collaboration with the University of Santiago de Compostela, has developed two standards of its own in product health and safety – Clear to Wear (CTW, health) and Safe to Wear (STW, safety) – which incorporate the most demanding world regulations in these areas.

Responsibility in the production of safe products is not solely limited to the supervision and control of processes typical of the textile industry: The auxiliary chemical industry and its suppliers also play a fundamental role. Therefore, Inditex’s strategy of action includes audits throughout the supply chain and training and advisory sessions for the design team, as well as technology audits and training for suppliers.

Programmes to implement and comply with Clear To Wear and Safe To Wear standards

In 2013, Inditex intensified its collaboration with 28 benchmarked laboratories in 7 countries where the Group’s main production clusters are located. These laboratories belong to reputed international suppliers and perform all analyses and tests intended to guarantee that products meet CTW and STW requirements.

This collaboration includes Inditex programmes to supervise the quality of laboratory analysis results and correction of any problems detected. The programmes required 10 auditing visits and the performance of more than 1,900 correlation analyses and 6 corrective actions.

The key instrument in the supervision of compliance with CTW and STW standards is the Picking Project. This is a programme that supervises the health and safety of the product during the production stage and seeks to detect the right implementation of the standards as early as possible in the manufacturing chain. The project, which was launched in 2012 and continued during 2013, involves the performance of technical inspections of factories during the final stage of the production of the product, the random selection of a representative number of finished garments before the end of the manufacturing process and the performance of tests and analyses on the garments to ensure that they meet the provisions of CTW and STW.

The development of the Picking Project in 2013 involved more than 41,500 inspection visits to factories and 1 million tests and analyses.

Ready to Manufacture Programme

The Ready to Manufacture (RTM) is the first world programme of Good Manufacturing Practices (GMP) intended specifically to prevent the inclusion or production of undesired substances during product manufacturing as a consequence of the technological processes used or the quality of the auxiliary chemical substances.

As part of the programme, a manufacturing code was drawn up together with a series of manuals containing guidelines and advice with the collaboration and guidance of experts in product health and textile manufacturing. These manuals serve as guidelines and help suppliers to control and improve their manufacturing processes, to select and manage the dyes, pigments and auxiliary chemical substances they use and to decide on the analytical tests they will perform to ensure compliance with CTW requirements. The RTM reference manual is intended to facilitate the incorporation of CTW in its entirety, while each of the guideline manuals is intended to reduce or eliminate incidents of non-compliance caused by a specific parameter regulated by CTW. In 2013, guideline manuals were drawn up for the following parameters: arilamines, formaldehyde, pH, colour solidity and fibre composition.

The Ready to Manufacture programme is complemented with specific training and supervision technical audits to ensure their implementation in all units of the supplier supply chain and investigate the source of any defects detected in order to facilitate the search for solutions.

The development of the pilot experience of the RTM programme in 2013 involved the performance of more than 2,200 audits and/or technical support visits.

The List, by Inditex

During 2013 Inditex developed a pioneering programme in the fashion industry entitled The List, by Inditex, which aims to deal with all productive units manufacturing dyes, pigments and auxiliary chemicals, performing processes liable to produce or transmit substances which, should they be present in finished articles, could cause a risk of non-compliance with CTW. This makes it possible to extend product health and safety controls to those industrial sectors that supply other products – above all, chemicals – used in the manufacture of garments.

The List, by Inditex programme is the result of a broad joint research programme with the University of Santiago de Compostela in close collaboration with the world’s leading manufacturers of dyes, pigments and auxiliary chemical products used in the manufacturing of textiles and leather products.

The first result of the development of this programme has been the compilation of the first world classification of thousands of dyes, pigments and auxiliary chemical products used in manufacturing textiles, footwear and accessories according to their compliance with CTW. The methodology followed in assessing the chemical products that appear on The List, by Inditex include the performance of chemical analyses, the technical inspection of manufacturing facilities, the supervision of the product quality control and health mechanisms used and the manufacturing companies’ commitments compared with good manufacturing practices and respect for the environment.

The development of The List, by Inditex in 2013 involved 11 leading multinationals in certain manufacturing clusters, allowing the classification of over 4,000 important chemical products in the textile and leather industry.

Cooperation programmes

Inditex believes it is fundamental to share and take full advantage of the experience acquired in the process of creating, implementing and supervising its CTW and STW standards. Two agreements have therefore been reached with business associations of textile exporters in Bangladesh and Turkey, two of the largest textile producers in the world, to increase their involvement in the programme to implement and supervise CTW and STW in their respective countries.

As part of the PIN Standard Project started in 2010 in collaboration with the universities of Dhaka and Santiago de Compostela and the Bangladesh Garments Manufacturers and Exporters Association (BGMEA), the creation and equipping of a benchmark laboratory was promoted in order to supervise the introduction of the product health and safety measures contained in the PIN Standard Project, equivalent to those established in CTW and STW. The laboratory was put into operation in 2013. These promotion and support actions on the part of Inditex also included the training of the laboratory’s technical and management staff and the transfer of knowledge and methods for the supervision and analysis of the laboratory’s own development.

Through its EKOTEKS laboratory, Inditex continued its work with the Istanbul Ready-Made Garment Exporters’ Association (ITKIB) to implement the Clear to Wear and Safe to Wear standards and the supervision of their compliance in the case of items produced in Turkey. Equally, it continued to strengthen its relationship with the Chinese authorities to ensure their involvement in introducing the CTW and STW standards and in supervising compliance with these standards in the case of products marketed in China.

Further information at http://www.inditex.com/en/sustainability/product/health_quality_standards

Tailored supplier training and technical advisory programmes

Inditex’s CSR department, working with reputed external advisers, has implemented a training and technological support programme for all players involved in the supply chain. The actions that have been developed were designed to suit each specific objective pursued and each target group.

Working groups on Clear to Wear and Safe to Wear standards were also created with suppliers and producers. These groups were adapted to the geographical, technological, environmental and cultural characteristics of the different regional production clusters.

Attendees to supplier training and technical advisory programmes

| Year | Meetings | Attendees |

| 2013 | 77 | 847 |

| 2012 | 32 | 514 |

Expert units have been created in all of the brands of the Inditex Group in the area of product health and safety in order to give ongoing training to the purchasing and design teams of each brand in all matters related to product health and safety and to provide them with in situ technical assistance, as well as reduce the time required to detect possible incidents of non-compliance and provide the solutions or technical support best suited to the specific type of product in each brand.

Internal product health and safety teams

| Year | Staff in internal teams |

| 2013 | 53 |

| 2012 | 43 |

In order to identify and eliminate potential risks in design and manufacturing processes as early as possible, specific training programmes have been designed and developed in the health and safety for Inditex staff.

Internal teams training in product health and safety

| Year | Courses | Attendees |

| 2013 | 78 | 773 |

| 2012 | 39 | 603 |

Animal welfare

In 2013, Inditex continued to strengthen its commitment to animal welfare. As a result of this commitment, the company signed up to the Fur Free Retailer Program promoted by the international coalition of animal protection organisations, the Fur Free Alliance.

Further information at http://www.inditex.com/en/sustainability/product/products_animal_origin

Angora

Inditex requires its suppliers to follow animal welfare recommendations concerning angora rabbits established by the various animal protection organisations with which Inditex is regularly in contact.

Similarly, Inditex has made additional farm visits and has carried out a process of independent certification of the angora production farms in its supply chain in order to confirm that they meet Inditex requirements. In this sense, Inditex has agreed not to place further orders with suppliers of products containing angora wool until the corresponding facilities have been inspected once again and the results have been checked against Inditex auditing protocol.