4. Sustainability of the supply chain

The final objective of the CSR strategy regarding the supply chain is to guarantee its sustainability.

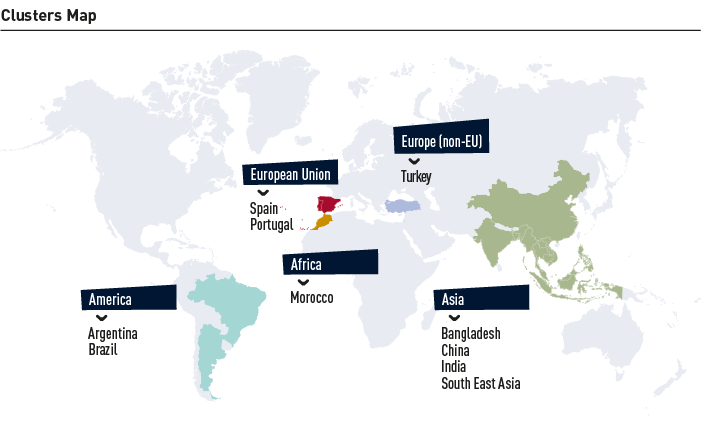

Inditex therefore works by grouping its suppliers into clusters, which are defined as areas for dialogue and multilateral cooperation. The Group has ten clusters in the geographic areas where it has a larger and more significant presence: Spain, Portugal, Morocco, Turkey, India, South East Asia, Bangladesh, China, Brazil and Argentina. These clusters account for some 87% of Inditex’s total production.

| Cluster | Internal team | External team |

| Spain | 13 | 11 |

| Portugal | 1 | 15 |

| Morocco | 2 | 10 |

| Turkey | 6 | 22 |

| India | 6 | 49 |

| Bangladesh | 6 | 38 |

| China | 6 | 346 |

| Brazil | 1 | 44 |

| Argentina | 1 | 29 |

| South East Asia | 1 | 53 |

| Total | 43 | 596 |

A new cluster was created for the countries of South East Asia in 2013. Based in Vietnam, it encompasses countries such as Cambodia, Indonesia, Thailand and the Philippines.

In 2013 the clusters continued to grow and make progress on their objective of improving working conditions in the textile industry, contributing to creating value in the company through the following actions:

|

|

|

| Objectives | Spain | Portugal |

| Primary objective 2013 | To encourage purchasing practices that guarantee the sustainability of the supply chain. | To maintain a close and fluid relationship with suppliers and to strengthen their compliance with their obligations, particularly in the area of wages and taxation. |

| Monitoring | ||

| Pre-assessment audits | 33 | 243 |

| Social audits | 88 | 379 |

| Special audits | 3 | - |

| Production audits | - | - |

| Individual sessions with suppliers |

- | - |

| Capacity building | ||

| Suppliers trained in production traceability. |

124 | |

| A total of 241 employees in central offices received specific training in CSR. | The cluster continued its relationship with the Catholic University of Oporto, providing training and experience in social audits to postgraduate students. | |

| Continual improvement | Joint work between the CSR team and the different departments of the company, in particular the purchasing departments. | In the area of salary and taxation, a diagnostic analysis was carried out to determine supplier compliance and compliance in matters of wages and taxes, and specific corrective measures were drawn up to deal with the breaches detected. |

| Stakeholder engagement |

Coordination of the global implementation of the Framework Agreement with IndustriALL. Member of the Accord on Fire and Building Safety in Bangladesh Steering Committee. Representation of the company in international platforms such as Better Work, ETI, Global Compact. |

In the area of the IndustriALL Framework Agreement, tighter collaboration was established with the Portuguese textile union (FESETE), working together to guarantee the rights of manufacturer and supplier employees. |

|

|

|

| Objectives | Morocco | Turkey |

| Primary objective 2013 | To guarantee the traceability of production and to strengthen relationships with different stakeholders such as unions or business associations. | To assure the quality of the monitoring tools and extend the scope of collaboration projects in order to improve working conditions. |

| Monitoring | ||

| Pre-assessment audits | 15 | 338 |

| Social audits | 138 | 601 |

| Special audits | 244 | 14 |

| Production audits | 307 | 84 |

| Individual sessions with suppliers |

- | 108 |

| Capacity building | ||

| Suppliers trained in production traceability. |

25 | 134 |

| The collaboration with IndustriALL provided direct awareness-raising among those responsible for five Moroccan suppliers in the area of workers’ rights to freedom of association and collective bargaining. | Completion of the pilot training project for workers and managers in collaboration with IndustriALL, with a seminar attended by 49 participants and aimed at workers’ representatives and supplier management with the participation of the International Labour Organisation (ILO) and ITBIK (a Turkish national union). | |

| Continual improvement | In 2013 Inditex began cooperating with the Moroccan Textiles and Clothing Industries Association (AMITH) on projects intended to ensure suppliers comply with the standards established in the Inditex Code of Conduct. | The Joint Turkey Programme, in collaboration with IndustriALL and two other international brands, entered its implementation phase in various suppliers in order to improve the productivity of factories, promote more mature industrial relations, and improve social dialogue and motivation among workers. |

| Stakeholder engagement |

Collaboration with Medicus Mundi in order to improve the health and welfare of workers in the supply chain.

The project is currently in its first diagnosis phase. |

Collaboration with the NGO Association for the Support of Contemporary Living (CYDD) in the area of preventing and remedying child labour through the From Production Back to Education project. EverGreen Programme; a pilot project with two suppliers in order to minimise and control waste dumping in production, with the participation of academics and experts in engineering. |

|

|

|

| Objectives | India | Bangladesh |

| Primary objective 2013 | To guarantee the traceability and sustainability of the supply chain as a continuation of the work carried out with the Vidya project. | To create programmes and practical alliances to prevent fire and promote the safety of workers in the textile industry. |

| Monitoring | ||

| Pre-assessment audits | 186 | 42 |

| Social audits | 239 | 242 |

| Special audits | 514 | 479 |

| Production audits | - | 62 |

| Individual sessions with suppliers |

172 | 63 |

| Capacity building | ||

| Suppliers trained in production traceability. |

155 | 147 |

| A project was started to improve the conditions of domestic workers by providing training in labour rights to 23 suppliers and more than 350 agents. Collaboration with St. Johns Medical College in Bangalore in training on women’s health in the textile industry, which benefited more than 350 workers (Sakhi Project – meaning “friend” in Hindi). |

Design and implementation of a programme in collaboration with an engineering firm intended to ensure that all manufacturers producing for Inditex in the country guarantee the safety of their workers. In 2013, visits were performed at 244 factories and structural assessments were made of more than 111 buildings. |

|

| Continual improvement | Work began with the NGO Pratham (an entity specialising in children’s education) for the implementation of the Plan for the Prevention and Remediation of Work by Minors through the From Production Back to Education project. | With a view to guaranteeing lasting improvements in workers’ conditions in the textile industry, Inditex is a member of the Accord on Fire and Building Safety in Bangladesh. The company played an active part in drawing up the Accord and was appointed a member of its Steering Committee. |

| Stakeholder engagement |

The Sowbhagyam project was initiated with a specialised NGO as a continuation of the Sumangali project, carrying forward its awareness-raising efforts on the rights of workers in communities in southern India and benefiting more than 10,000 families.

Proactive participation at the Tirupur Stakeholders Forum and the Tamil Nadu Multi-Stakeholder initiative promoted by the Ethical Trading Initiative for the collaboration of NGOs, unions and government in eradicating abusive employment schemes in southern India. |

Active participation in the multilateral Buyers’ Forum and constant dialogue with national and local unions as well as with BGMEA, the National Association of textile manufacturers and exporters. Collaboration with the AWAJ Foundation, a renowned Bangladeshi entity engaged in protecting workers in the textile sector through the From Production Back to Education Programme for the development of the Plan for the Prevention and Remediation of Work by Minors. |

|

|

|

| Objectives | China | Brazil |

| Primary objective 2013 | To strengthen the working conditions of suppliers working for Inditex in China. | To assure the traceability of production and the continuity of cooperation programmes for the promotion of human rights. |

| Monitoring | ||

| Pre-assessment audits | 354 | 5 |

| Social audits | 574 | 151 |

| Special audits | 127 | 19 |

| Production audits | 20 | 108 |

| Individual sessions with suppliers |

130 | 2 |

| Capacity building | ||

| Suppliers trained in production traceability. |

538 | - |

| In the development of the Framework Agreement between Inditex and IndustriALL, joint visits were made to six suppliers to analyse the state of working conditions in factories and the role of the unions in the region. Pilot project to identify and improve working conditions in the domestic sector, in which 32 domestic workers related to some suppliers were visited and interviewed. |

Training for suppliers through fashion and business management courses imparted by Uniethos and advice for manufacturers given by SENAI (National Industrial Training Service) on people management, financial and business management, stock control, production control and other areas. | |

| Continual improvement | The constant monitoring and work of the CSR teams with suppliers allowed 73 factories to successfully implement their Corrective Action Plans in 2013. | Specific supplier development programme resulting from an alliance between Zara Brazil and Uniethos. Eight suppliers and 27 manufacturers took part in the project in order to improve their working conditions and increase their competitiveness. |

| Stakeholder engagement |

Collaboration with the Zhejiang Sci-Tech technological University on the specific training of Inditex internal auditors in textile processes and production capacity. | Cooperation and joint work of 13 international brands in the sector present in the country to identify and share information on aspects of supply chains and possible joint solutions. |

|

|

|

| Objectives | Argentina | South East Asiao |

| Primary objective 2013 | To guarantee the traceability of the supply chain. | To strengthen the supply chain in the region of South East Asia. |

| Monitoring | ||

| Pre-assessment audits | 8 | 60 |

| Social audits | 100 | 81 |

| Special audits | 219 | - |

| Production audits | 239 | - |

| Individual sessions with suppliers |

24 | - |

| Capacity building | ||

| Suppliers trained in production traceability. |

46 | - |

| The awareness of the internal teams was strengthened by constant communications and training sessions, including three general meetings with all the local purchasing teams and the management of Zara Argentina. 24 training sessions were performed with suppliers. |

Training of the head of the new cluster in charge of the teams in Spain and India. | |

| Continual improvement | In collaboration with the National Institute of Industrial Technology (INTI) various suppliers were analysed as part of a pilot project to assess specific indicators related to the factories’ production capacity in order to strengthen Inditex’s supply chain. | The situation of Inditex’s supply chain in Vietnam, Thailand, Cambodia, Malaysia and Indonesia was assessed in order to identify areas of CSR to be worked on. |

| Stakeholder engagement |

Joint work with IndustriALL representatives to assess workers’ conditions and meetings with three local textile unions in four suppliers representing the sector. | The first steps were taken to establish programmes and actions involving direct collaboration with different local and international stakeholders. |