2. Environmental indicators

The Inditex system of indicators shows the measureable results of our environmental commitments in terms of natural resources and energy consumption, waste generation and atmospheric emissions. These indicators are expressed in absolute and relative data according to the number of garments released on the market, reflecting the efficiency of all areas of the company. These relative indicators show that greenhouse gas (GHG) emissions have been significantly reduced, a reflection of the successful integration of innovative environmental management into all phases of the business. The scope of the indicators includes Inditex’s own premises in Spain and all the stores owned by the Group worldwide.

The guidelines set out in the Intergovernmental Panel on Climate Change, IPCC (Guidelines for National Greenhouse Gas Inventories, 2007) and the World Resources Institute GHG Protocol (2008) are used to calculate GHG emissions. The emissions factors used are as follows:

- Natural gas: 0.2025 kg co2eq/kWh

- Diesel: 2.6919 kg CO2eq/litre

- Electricity: 0.299 kg CO2eq/kWh

The emission factors applied to natural gas and diesel are taken from the GHG Protocol for Stationary Combustion v.4.0 by the World Resources Institute (WRI). The emission factor for electricity is from the WRI database of emission factors (August 2012 version) and corresponds to the emissions associated with the electricity mix for Spain.

The conversion factors used to calculate energy consumption are:

- 1 tonne of oil equivalent (toe) = 41.868 GJ

- 103 m3 of natural gas = 0.9315 toe

- 1 tonne diesel = 1.035 toe

- Oil density = 0.832 kg/litre at 15°C (Joint Research Centre, 2007).

Relative indicators are calculated according to the following formula:

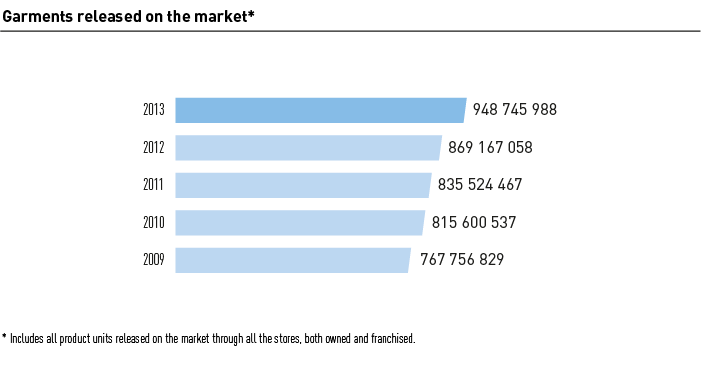

Ratio = (absolute value of the year/number of garment released on the market during the year) x 1000.

The environmental indicator system includes data collected from 1 February 2013 to 31 January 2014.

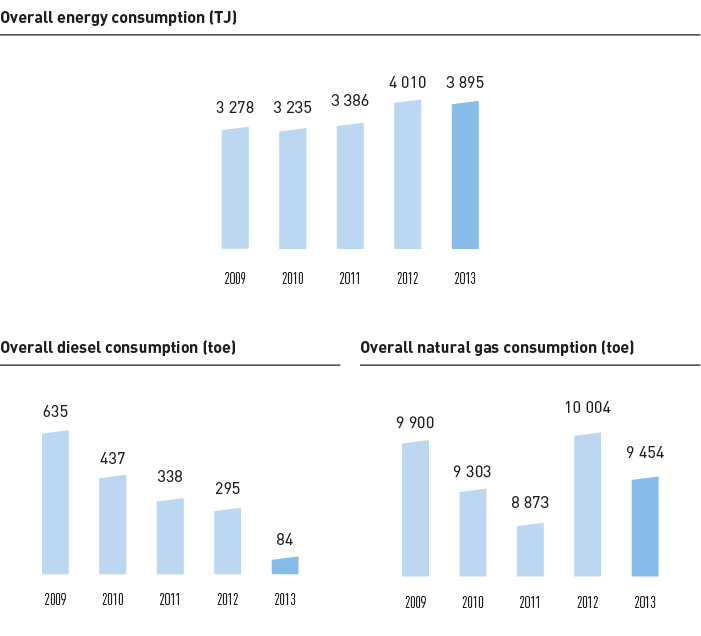

Energy consumption

Overall energy consumption of Inditex Group facilities, expressed in terajoules (TJ), comes from the use of fossil fuels (natural gas, propane and diesel) and electricity from the grid. It includes the energy consumption of all factories, headquarters, brand head offices, logistics centres and stores. The scope of the indicators includes Inditex’s own premises in Spain and all the stores owned by the Group worldwide.

Inditex’s overall energy consumption remained stable following the completion of work to extend the Group’s headquarters in Arteixo and the Massimo Dutti offices and logistics centre in Tordera in 2012. The lower natural gas consumption was mainly due to a decrease in trigeneration plant activity. Diesel consumption continued its downward trend due to the change from diesel boilers to natural gas and the closure of other diesel boilers at centres such as the Arteixo trigeneration plant.

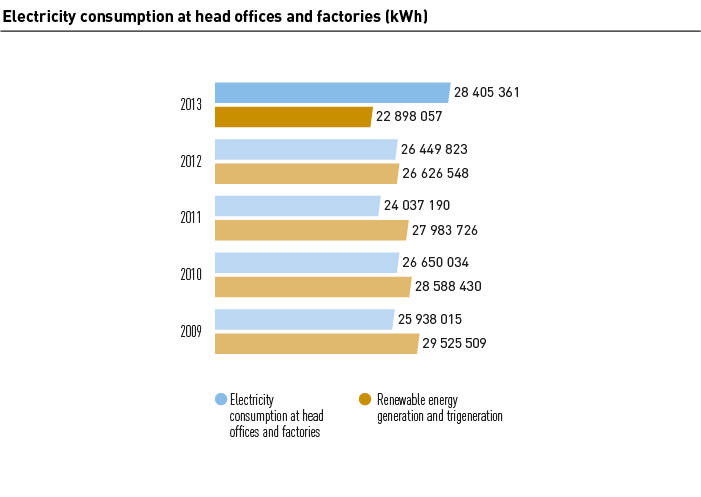

In head offices and factories

The company’s energy consumption scheme permits the combination of different energy sources, including renewable energies. Trigeneration plants, heating and process boilers, solar panels and wind generators now account for more than 45% of the energy consumed in head offices and factories.

Electricity consumption increased in 2013 compared to previous years due to the start of work to extend company headquarters and the Massimo Dutti office building. Natural gas consumption remained stable, registering a slight decrease due to a lower level of activity at the trigeneration plants. The Group continued to focus on efficiency and caring for the environment by replacing diesel boilers with natural gas. As a result, the company is consuming ever decreasing amounts of diesel, and SO2, CO and NOx emissions have been significantly reduced.

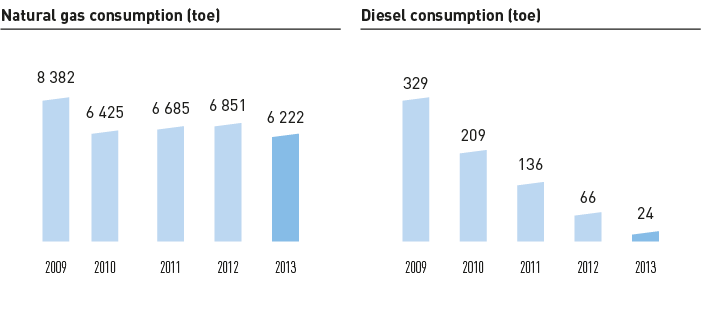

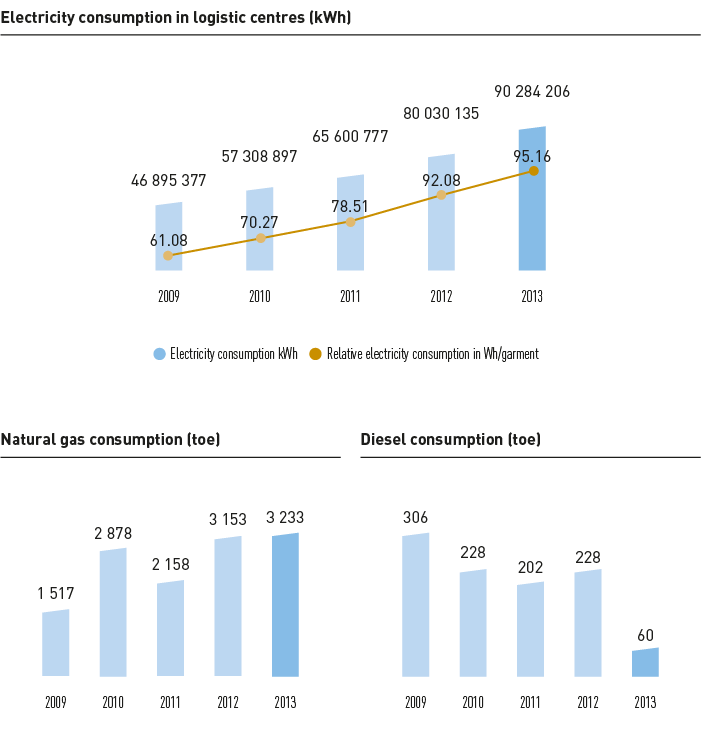

Logistics and transport centres

All garments manufactured by Inditex are distributed from the company’s logistics centres in Spain. Inditex has increased the automation of distribution operations at its logistic centres in recent years, which has resulted in an increase in electricity consumed per garment released on the market (Wh/garment). To counteract this effect, sustainable logistics centres are being designed based on international certifications such as BREEAM and LEED that ensure their efficiency.

Natural gas consumption remains stable, recording a slight decrease due to a lower level of activity at trigeneration plants. The Group continues to focus on efficiency and caring for the environment by replacing diesel boilers with natural gas. As a result, the company is consuming ever decreasing amounts of diesel, and SO2, CO and NOx emissions have been significantly reduced.

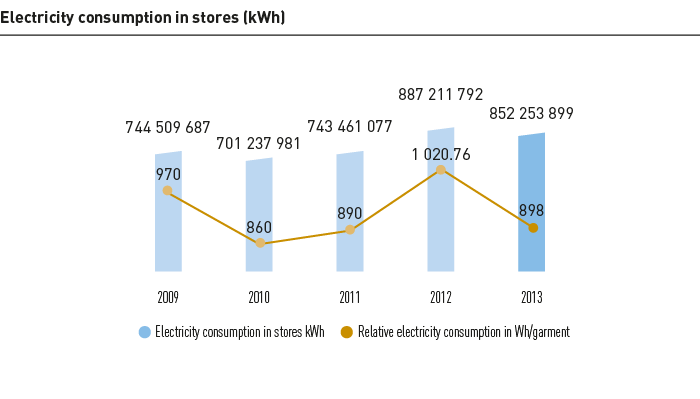

Stores

Electricity consumption at stores is without doubt very high. Therefore, a great deal of effort has been made to continue improving the eco-efficient store model with the aim of achieving a 20% reduction in electricity consumption per garment before 2020, using 2005 as the base year. Absolute and relative power consumption has been reduced compared to 2012 due to the construction and remodelling of eco-efficient stores, as well as more favourable weather conditions during 2013.

Inditex Greenhouse Gas Emissions (GHG)

The Group’s greenhouse gas (GHG) emissions are calculated and reported in line with the international directives of the Intergovernmental Panel on Climate Change (IPCC), Guides for National Greenhouse Gas Inventories (2007) and the World Resources Institute (GHG Protocol, 2008). The Inditex Group’s GHG emissions inventory includes direct and indirect emissions for the period 1 February 2013 to 31 January 2014.

A data history based on each of the scopes considered by the GHG Protocol is presented below.

-

Scope 1:Direct emissions. These are GHG emissions associated with sources under the Inditex Group’s control. It includes:

- Emissions associated with electricity and heat generation in owned premises. Emissions linked to occasional leaks (or isolated leaks) of HFC and PFC gases from air conditioning equipment are not included.

- Emissions from the use of own vehicles.

- Headquarters and all brand head offices (Pull&Bear, Massimo Dutti, Stradivarius, Oysho, Bershka, Zara Home, Tempe, Zara, Uterqüe)

- All group factories (Goa, Fios, Indipunt, Samlor, Stear, Denllo, Sabón, Inditex cogeneración)

- All logistics centres (Pull&Bear, Stradivarius, Tordera Logistics Centre, Bershka Logistics Centre, Sabón Logistics Centre, León Logistics Platform, Europa Platform, Meco Logistics Platform and Tempe Logistics Centres).

- Scope 2: Indirect emissions. Emissions associated with the generation of electricity the Inditex Group buys. The calculation was based on GHG emissions from the head office, brand offices, all Group factories, all logistics centres and all stores. Electricity used in international offices not included.

- Scope 3: Optional scope that includes indirect emissions associated with the goods and services supply chain. It includes emissions associated with the transport of garments from logistics centres stores by external logistics operators (truck, short-, medium- and long-haul air and ship), as well as emissions associated with electricity consumption in franchise stores.

| 2009 | 2010 | 2011 | 2012 | 2013 | |

| Scope 1 (t CO2eq) | 24 591 | 22 870 | 21 919 | 24 479 | 22 525 |

| Scope 2 (t CO2eq) | 310 635 | 309 602 | 291 413 | 290 120 | 283 466 |

| Scope 3 – Transport (t CO2eq) | 248 021 | 289 431 | 332 097 | 398 158 | 462 120 |

| Scope 3 – Franchises (t CO2eq) | - | - | - | 34 654 | 34 329 |

| Number of garments released on the market | 767 756 829 | 815 600 537 | 835 524 467 | 869 167 058 | 948 745 988 |

| g CO2eq per garment released on the market* | 436.63 | 407.64 | 374.66 | 361.95 | 322.52 |

* The efficiency ratio includes the emissions associated with the Group’s operations (Scope 1 and 2). The optional emissions (Scope 3) are not comparable with years before 2012 as new sources of emission have been included.

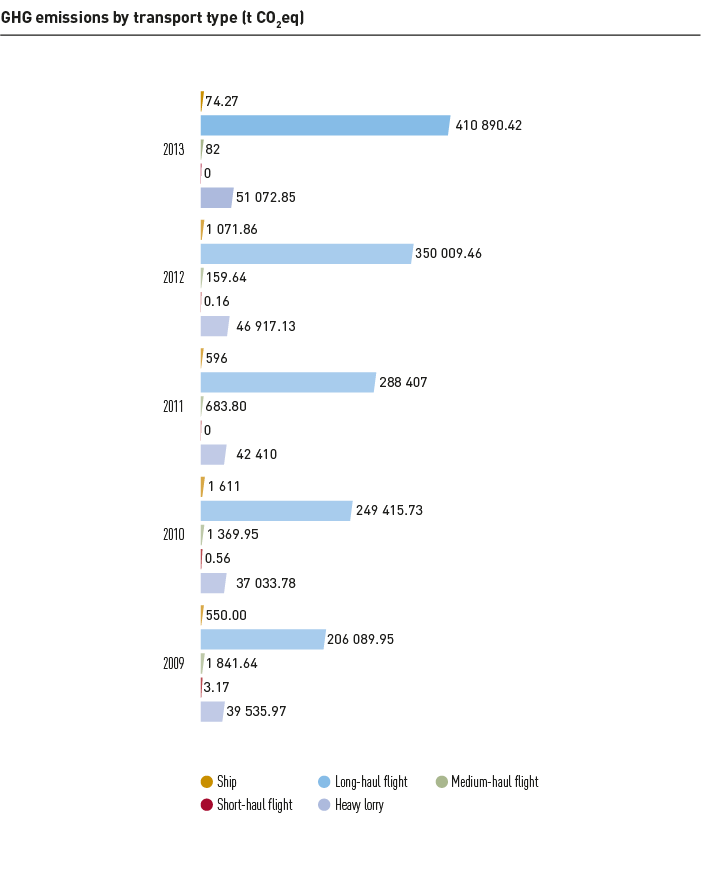

Scope 3 emissions detail

We calculate the GHG resulting from distribution and logistics operations carried out by external logistics operators based on the vehicles used to transport the product (Scope 3). Calculations were based on the weight of the product sent and the average number of kilometres travelled. The following emission factors, as proposed by the GHG Protocol, are used:

- Kg de CO2 / km truck= 0.8678

- Kg de CO2 / tonne and km short-haul flight (<463 km)= 1.96073

- Kg. de CO2 / tonne and km medium-haul flight (between 463 and 1108 km)= 1.47389

- Kg de CO2 / tonne and km medium-haul flight (>1108 km)= 0.61324

- Kg de CO2 / km ship= 0.0079

The general increase in GHG emissions in transport over recent years is due to the increase of products released on the market. It is worth noting that this increase in emissions from air transport on long-haul flights (>1108 km) is due to the increase in exports to countries such as China.

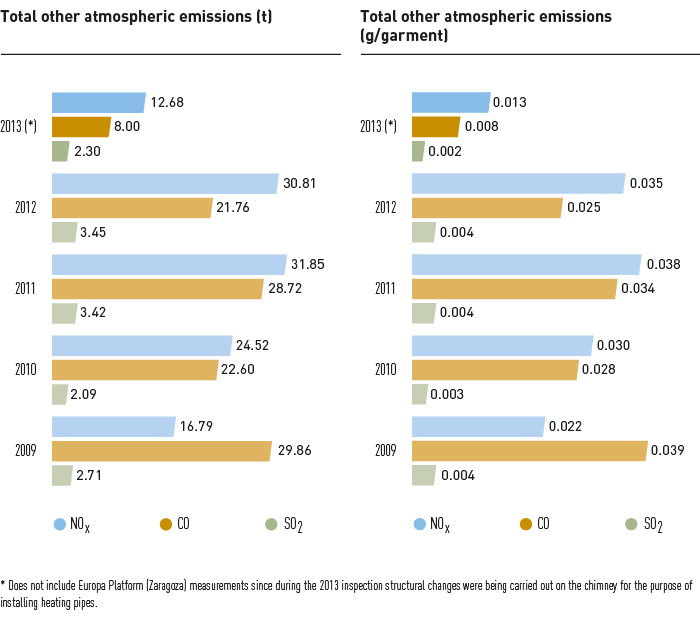

Other atmospheric emissions

All the focuses of emissions of the Inditex Group are submitted to periodic controls by an authorized inspection authority and have been found to be within the parameters set out in the legislation in force. The following is the annual evolution of other atmospheric emissions associated with the emissions focus of the Groups’s headquarters, all Inditex factories, brand head offices and logistics centres.

In 2013, decreased activity at Indipunt and the stopping of the bi-fuel engines at the Inditex trigeneration plant in Arteixo led to significant reductions in air emissions. Specifically, the reduction registered was of 99% and 59% respectively in each of the centres compared to emissions in 2012.

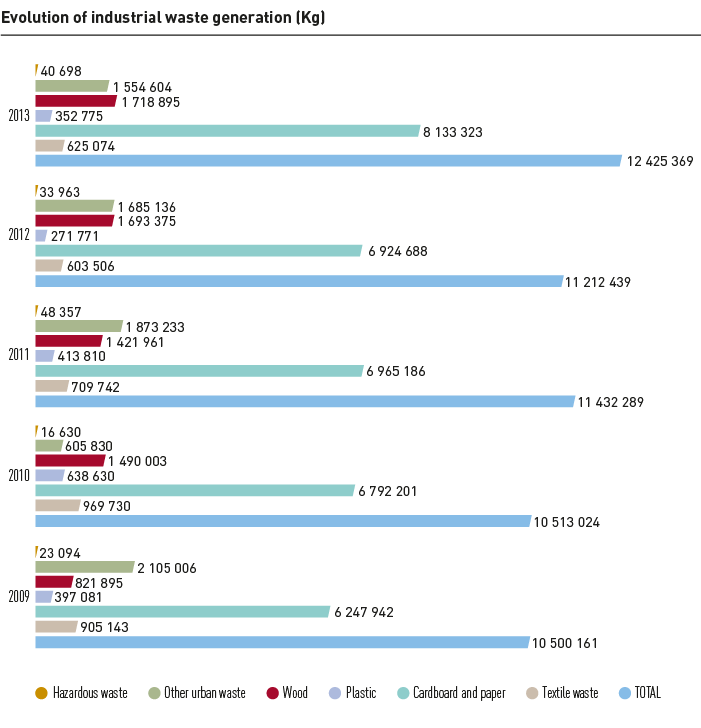

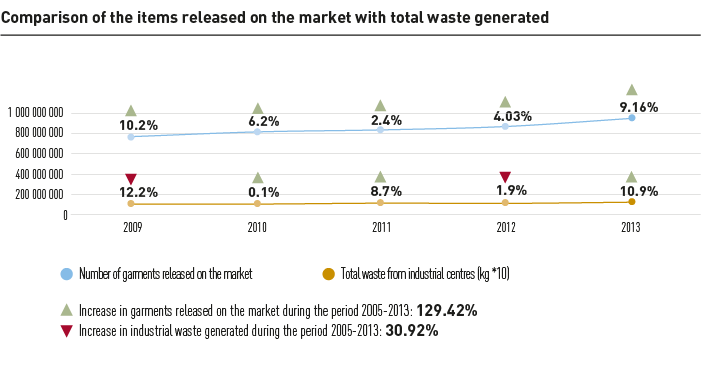

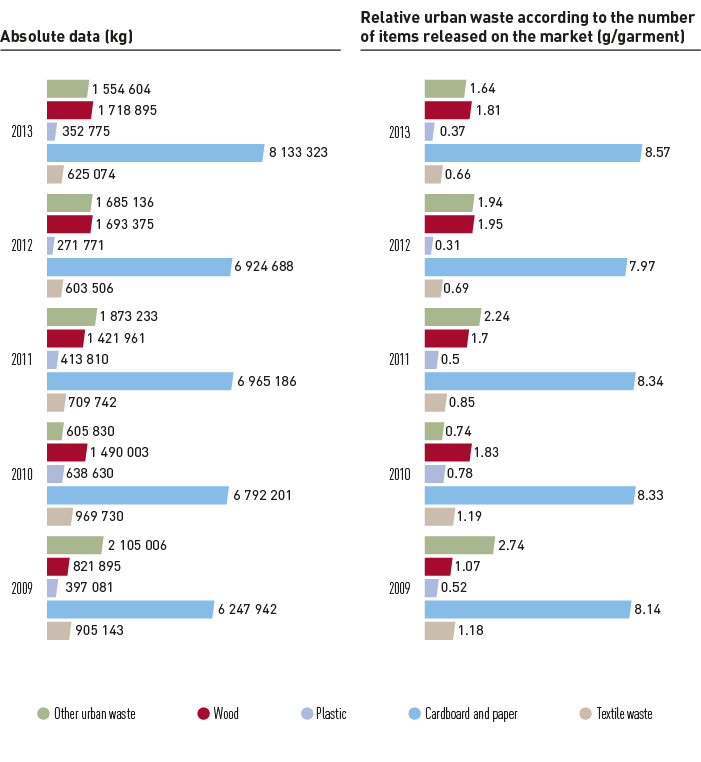

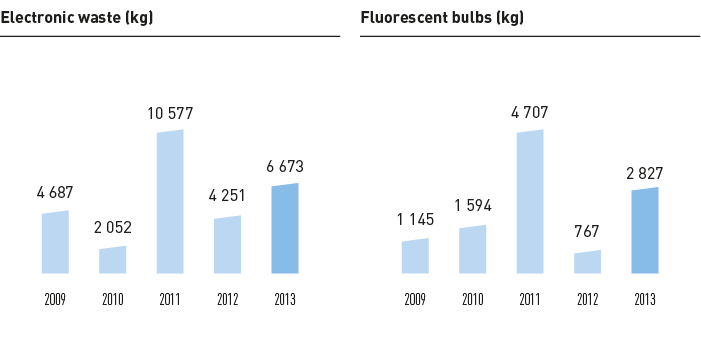

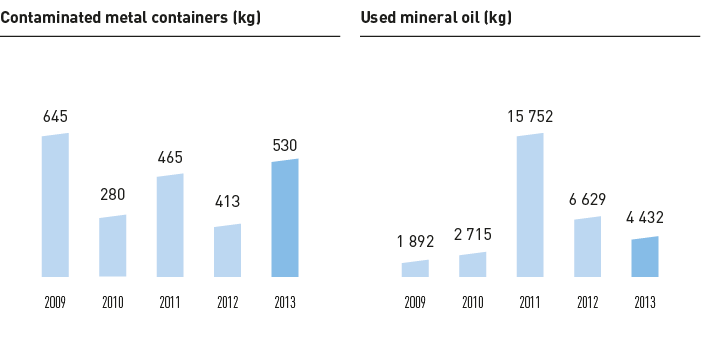

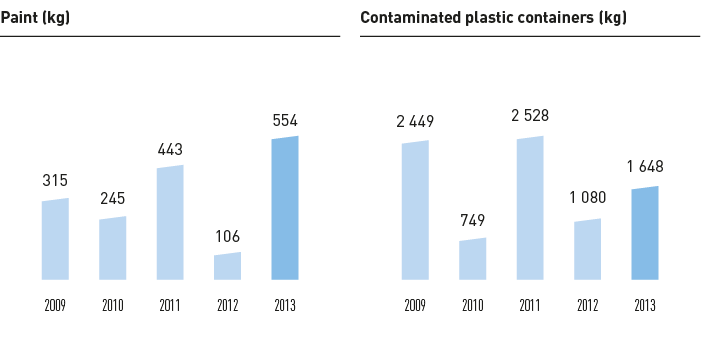

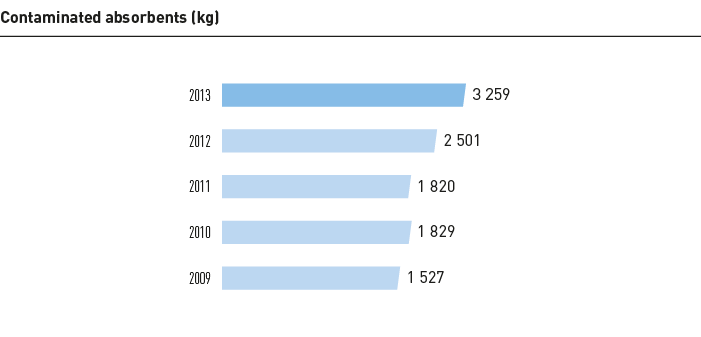

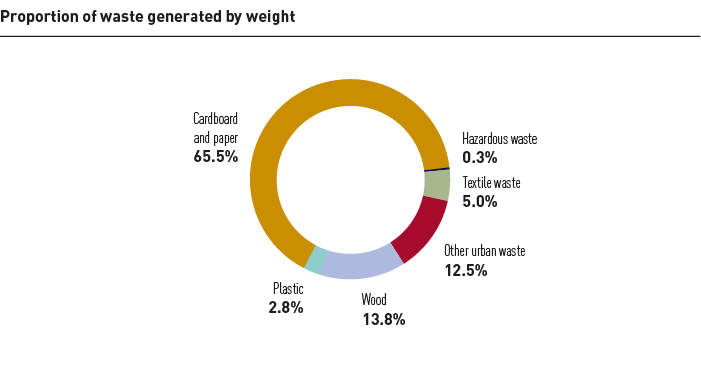

Waste generation and management

Thanks to the Waste Minimisation Plan and the efforts and commitment of all employees, using 2005 as the base year all types of waste were reduced despite the increase in garments released on the market. Waste generation data refers to the waste generated in headquarters, brand head offices, all Inditex factories and logistics centres. It does not include the waste generated in stores.

Annual generation of urban waste or similar

This waste is classified in accordance with the European Waste Catalogue (EWC) and its transposition into national and regional legislation.

Use of reusable alarms

The success of the reusable alarm system introduced in 2011 has made it possible to completely eliminate the use of single-use alarms. In addition to financial savings, this initiative provides an important environmental benefit, since reuse reduces the natural resource consumption and atmospheric emissions associated with security tag manufacture and recycling.

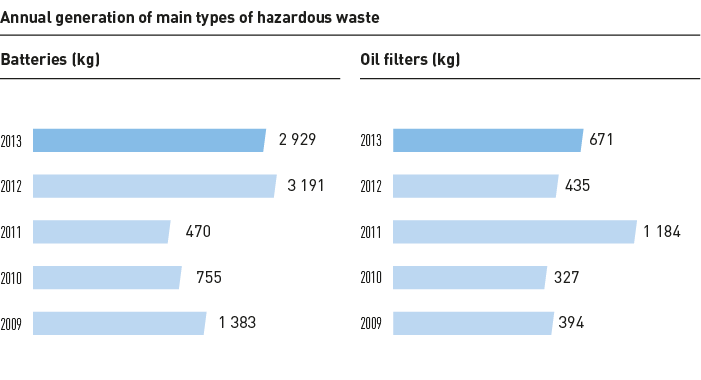

The increase in battery waste generation in 2012 and 2013 was due to the preventative maintenance of fire-fighting systems.

Destination of waste according to type and treatment

As part of the final stage of Inditex’s Waste Minimisation Plan, all waste generated by the company is collected and managed by a legally authorised body that sends the waste for recycling (in the case of security tags and paper), for composting or processing (wood, plastics), or to be managed in an environmentally-friendly way.

The packaging materials released on the market (paper and plastic bags, labels, protective elements) along with the products sold by Inditex are adequately managed by authorized bodies. Inditex subscribes to the Integrated Management Systems for Packaging and Wrapping available in countries that employ them. The company’s commitment to these systems means that each Inditex brand pays a non-profit management agency to collect and manage the waste generated by the stores. This management agency is established with the recognition of the authorities of each country (Ecoembes in Spain) to ensure that the waste generated by stores is collected, managed and recycled correctly.

In terms of the recovery of products released on the market, it is not viable to assess the volume generated nor its management on a worldwide level, given that there is no specific collection or management system for textile materials on the global level.

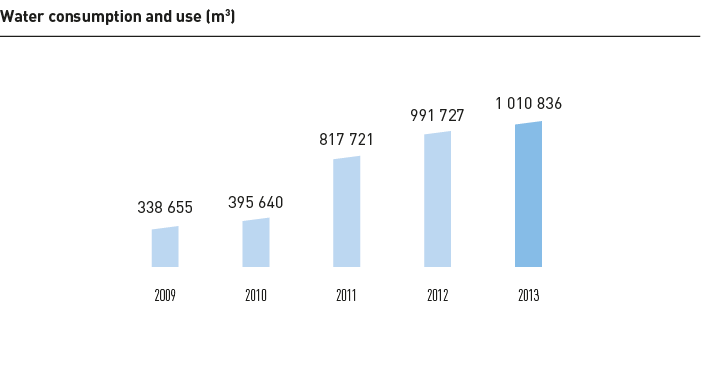

Data on water consumption comes from direct measurements and those received from suppliers (public water suppliers), offices, all Inditex’s factories, logistics centres and own stores.

The increase in water consumption in 2013 over previous years was mainly due to the opening of new stores and the new Massimo Dutti office building and logistics centre.

Water supplied to all the centres for use both in processes and for consumption comes from public, authorised supply networks with the result that Inditex has no impact on protected habitats.

Most of the water consumption is accounted for domestic use – cleaning and sanitation – and its discharge to municipal sewage systems is guaranteed.

In the area of industrial activities, water is mainly required for steam generation and industrial refrigeration in a closed cycle, where recirculation systems are used. Discharge of waste water from all installations was carried out via sanitation networks, in all cases with the corresponding administrative authorization. This requires periodic analyses to guarantee compliance with the law in force. The amount of wastewater can be calculated as equal to water consumed, as there are no productive processes that consume water and the cooling systems use a closed cycle. In order to ensure better water use, the Indipunt factory (Narón) is installing a waste water recovery system capable of reusing 90% of the water discharged.