Waste generation and management

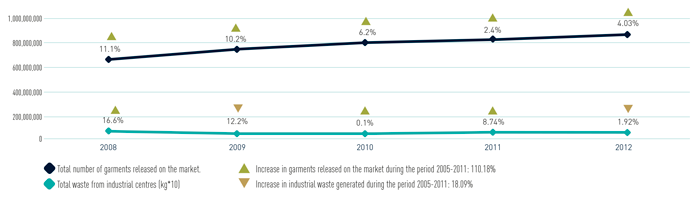

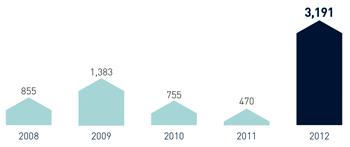

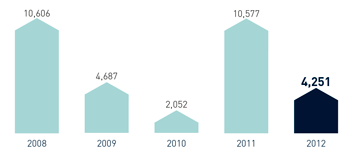

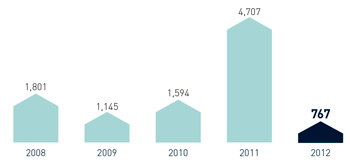

Thanks to the Waste Minimisation Plan and the efforts and commitment shown by all employees, all kinds of waste were reduced, despite the increase in garments manufactured.

The waste generation data refers to the waste generated in Spain during the calendar year. The waste generated in the stores is not included.

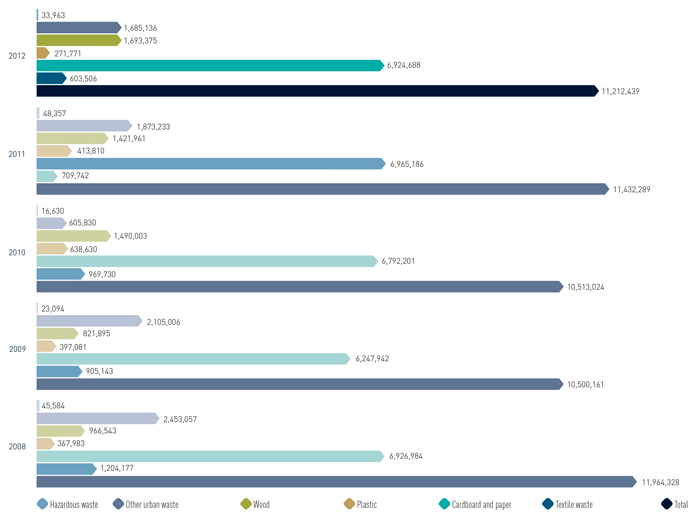

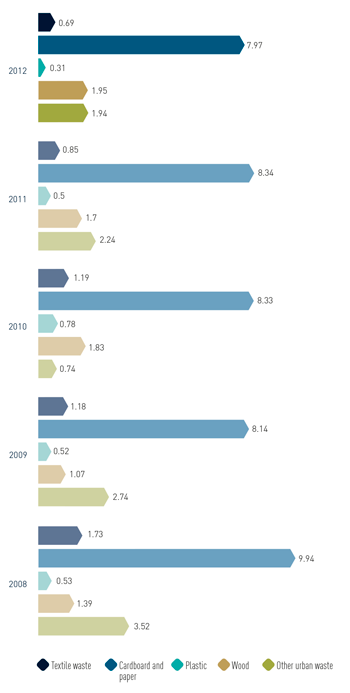

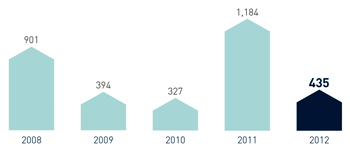

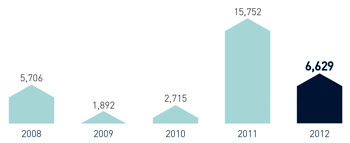

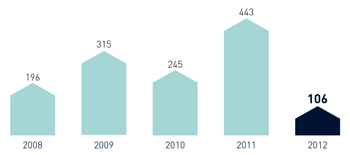

Change in industrial waste generation (kg)

Waste generation from head office, chain head offices, factories and logistical centres and our own stores was considered.

Comparison of garments released on the market with the total industrial waste generated

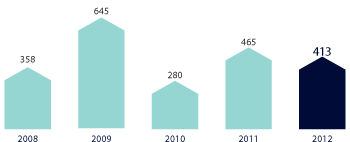

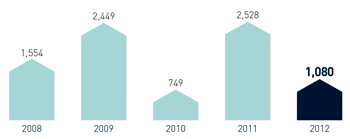

Annual generation of urban and similar waste

The waste is classified in accordance with the European Waste Catalogue (EWC) and its transposition into national and regional legislation.

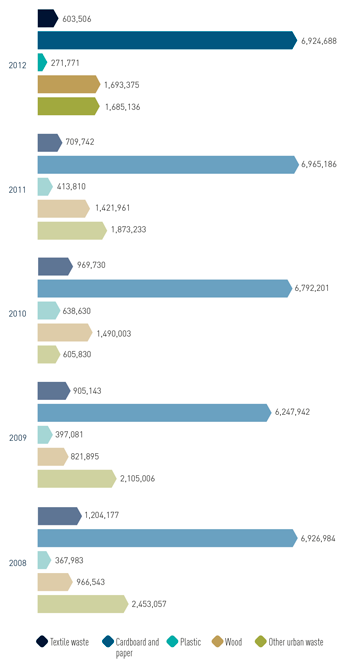

Absolute data (kg)

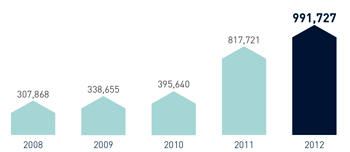

Relative urban waste data as a function of number of garments released on the market (g/garment)

Use of reusable alarms

The success of the reusable alarm system introduced in 2011 has meant single-use alarms have been completely eliminated. In addition to financial savings, this initiative provides an important environmental benefit as reuse reduces natural resource consumption and atmospheric emissions associated with their manufacture and recycling.

Annual generation of main types of hazardous waste

Batteries (kg)

The increase in battery waste generation in 2012 was due to the preventative maintenance of the fire-fighting systems.

Electronic waste (kg)

Fluorescents (kg)

Oil filters (kg)

Contaminated metal packaging (kg)

Used mineral oil (kg)

Contaminated absorbents (kg)

Paints (kg)

Contaminated plastic packaging (kg)

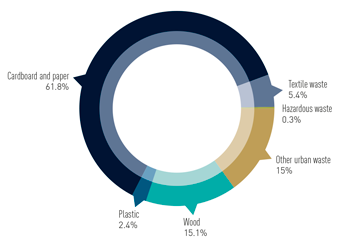

Waste allocation according to type and treatment

As the last step of the Waste Minimisation Plan, all waste generated by Inditex is collected and managed by a legally authorised body that sends the waste for recycling (in the case of alarms or paper), for composting or processing (wood, plastics), or managed in an environmentally friendly way.

With respect to the recovery of products released on the market, it is not viable to assess the volume generated nor its management on a worldwide level, given that there is no specific collection or management system for textile materials.

The packaging materials released onto the market (cardboard and plastic bags, labels, protective elements) associated with the products marketed by Inditex, are appropriately managed by authorised agents. Inditex adheres to the Integrated Management Systems for Packaging and Wrapping available in every country where it does business. The commitment to these systems means that each Inditex chain pays a non-profit management agency whatever it costs to collect and manage the waste generated by the stores. This management agency is established with the recognition of the authorities of each country (in Spain, Ecoembes) to ensure that the waste generated by the stores is suitably collected, managed and recycled.

Proportion of generated waste

Consumption and use of water

The water consumption data are taken from direct consumption measurements and from supplier invoices (public supply networks). Water consumption at head offices, logistics centres, factories and stores throughout the tax year are included.

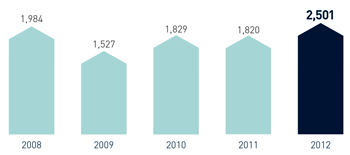

The increase in water consumption in 2012 over previous years is mainly due to the opening of new stores, the Massimo Dutti office building and logistics centre and the extension work on the Inditex head office.

Water supply at all the centres for both processes and for consumption comes from public, authorised supply networks with the result that Inditex has no impact on protected habitats.

Most of the water consumption is in the commercial network for domestic use - mainly cleaning and consumption. For this reason it is impossible to recycle. In the area of industrial activities, water is mainly needed for steam generation and industrial refrigeration in a closed cycle, where recirculation systems are used.

Wastewater from all of our sites is dumped into sewage systems, with appropriate administrative authorisation in all cases. This implies that analysis is done periodically to guarantee compliance with current law. The amount of wastewater is estimated as the same as water consumed, as there are no productive processes that consume water and the cooling systems use a closed cycle. To improve water use, the Indipunt (Narón) factory is installing a wastewater recovery system with the capacity to reuse 90% of water discharged.

Water consumption (m3)*